Menu

At the beginning of the 21st century, offshore production became more complex with each new project, moving into deep waters, and to areas with harsh environments. The design and operation of these new developments were pushing the limits of available multiphase flow simulation capabilities. At the same time, the demands on efficient risk and cost control increased. The development of LedaFlow started with the objective to give the industry the tool it needed to tackle those new challenges.

LedaFlow shall be the preferred multiphase flow assurance provider

LedaFlow Engineering includes all features needed for the flow assurance and well performance workflow and is routinely applied in all phases of the life cycle of a project.

Constant fluid properties

Black Oil

PVT tables

Composition tracking

Steam / Water

Generic single component (with phase change).

Inhibitors in all 3 phases

Drilling muds, tracers, dead oils

Newtonian and non-Newtonian fluids

Compressible gas.

3 energy equations

Partially and fully buried pipe

Annulus (symmetric and asymmetric)

LedaFlow Slug capturing®

Slug size

Slug statistics module.

Emulsion modelling

Corrosion

Erosion

Hydrate margins and transportation

Wax margins and deposition -Sand deposition indicators

Flow induced pulsation (FLIP)

Force calculations in bends.

Separator

Pig (simple and bypass)

Pipe heat source

Flexible pipe wall

Valves (incl. hydro short and long path)

Leak

Gas lift valve

Controllers

Multiphase pump

User defined phase split.

Mass and pressure boundaries

Sources

Well with IPR definition.

2D plotting

3D visualization

Device/Boundary chart

Automatic turndown curve generator.

Graphical User Interface

Well builder

Excel Add-in

User preferences

Parametric and sensitivity study analysis

Profile tools

Tuning

Simulation manager

Input and output file generator

Purging tool

Model change logger

OLGA to LedaFlow converter

Integrated scripting environment.

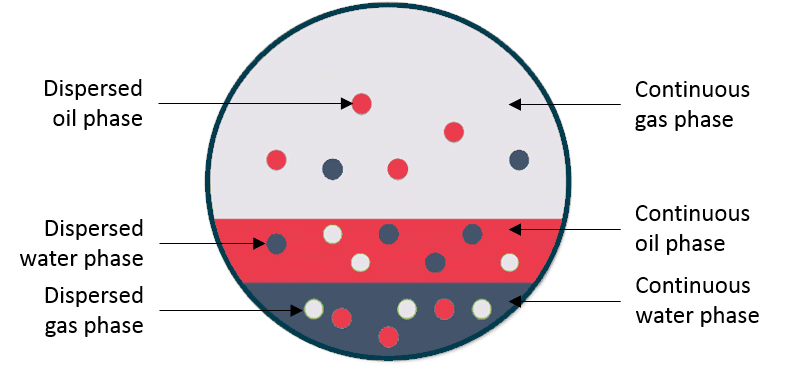

LedaFlow solves the mass balance equations for all nine fields (gas, oil and water in the bulk and two dispersed fields per phase) while momentum and energy equations are solved for the three continuous phases. This detailed approach enables closer matching to laboratory and field data.

As LedaFlow solves separate energy equations for all three phases, much more accurate information can be determined during stratified flow and during blow down conditions where the temperature of the slower moving liquids at the bottom of a pipe can differ considerably from the gas flowing above. In addition, a buried pipe model provides the user with a heat conduction model from the inner surface of the pipe through to the exterior surface of the soil. This is particularly important for estimating corrosion rates and pipe-wall temperatures, information that is critical for material selection and for hydrate risks prediction.

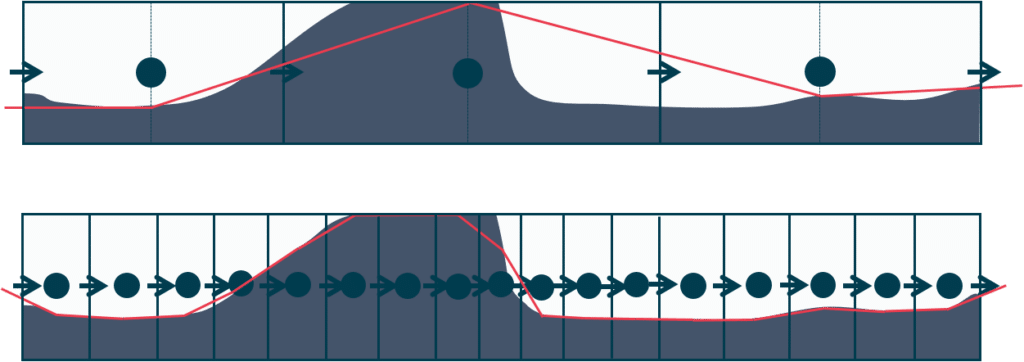

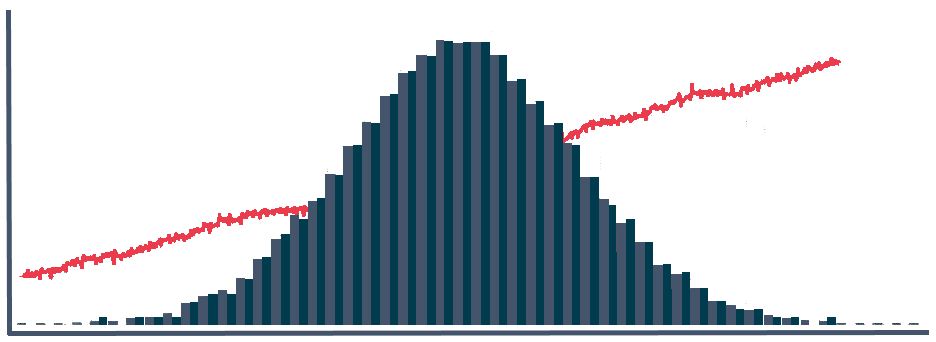

LedaFlow uses a Unit Cell Model for modelling terrain and riser induced slugging. It also includes Slug Capturing which is the first commercially available solution to accurately predict hydrodynamic slug behavior without user input. It captures the initiation and growth of waves and hydrodynamic slugs using higher-order numerical methods. The analysis of slugs is facilitated by slug statistics and slug size tools.

The hydrate transport model calculates the formation and transport of hydrate particles. It is used to evaluate the possibility to operate inside the hydrate risk region by taking into account the effect of inhibitors, the changes in temperature due to the heat of reaction and the effect on fluid properties. This model complements the hydrate management tools which are traditionally used by the industry and which are also available in LedaFlow: hydrate curve configuration, inhibitor injection, electrical heating, hydrate margins calculation, etc.

The wax deposition module simulates creation, melting and deposition of wax. It is used to determine the pigging frequency required to keep wax deposits under control. The model takes into account the changes in pressure and temperature as well as the effect on fluid properties. This model can be combined with other tools traditionally used for wax risk management studies, e.g. inhibitor injection, electrical heating, wax margin calculations, etc.

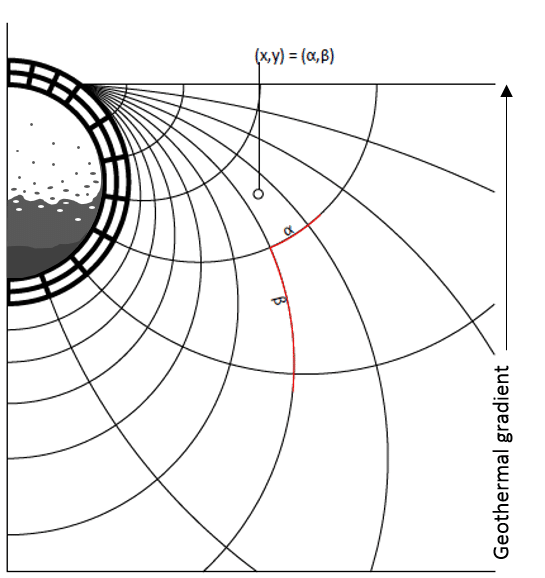

The use of representative profile models during the design phase of new multiphase projects is critical. LedaFlow includes a group of tools to generate profiles that are suitable for dynamic simulations. These tools include several filtering methods, a simplification tool based on the methodology developed by Erich Zakarian [1] and a an algorithm that can generate a realistic profile when data is missing.

Although LedaFlow has been developed for the oil and gas industry, it is also applied for simulating networks of steam pipes or pipes containing pure liquid water, thanks to a special non-equilibrium mass transfer term that models boiling and condensation.

Fueled by BENZIN AS